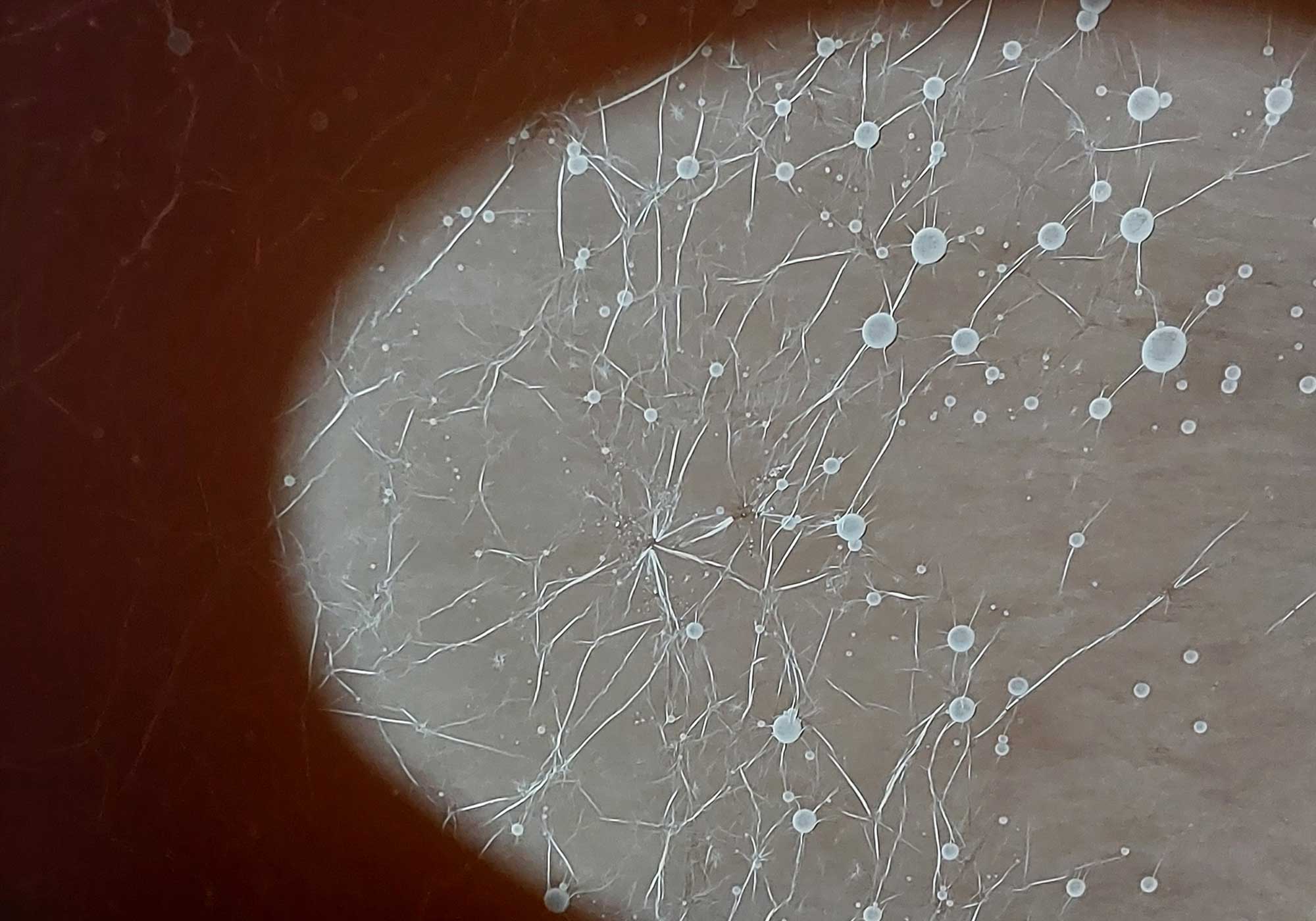

Let’s Clear Things Up: How to Avoid Blobs, Hazes, and Settling in the Bottle

SUBSCRIBERUnderstanding and knowing how to address various issues that can create an unsightly spirit can help you put your best foot forward as a distiller.

10 articles in this category

Understanding and knowing how to address various issues that can create an unsightly spirit can help you put your best foot forward as a distiller.

The term “column still” can apply to various designs with different purposes. To make sure you have the right still for the job, it’s best to understand the role and function of each of these types.

Choosing between steam, direct-fire, electric, and oil-heated equipment is a matter of budget, taste, and local code enforcement.

For most small-scale producers, batch-distilling is the standard approach to creating a variety of products.

To better understand the heads, hearts, and tails fractions, distillers should first have a firm grasp on what’s happening as their distilling media turn to vapor and then back to liquid.

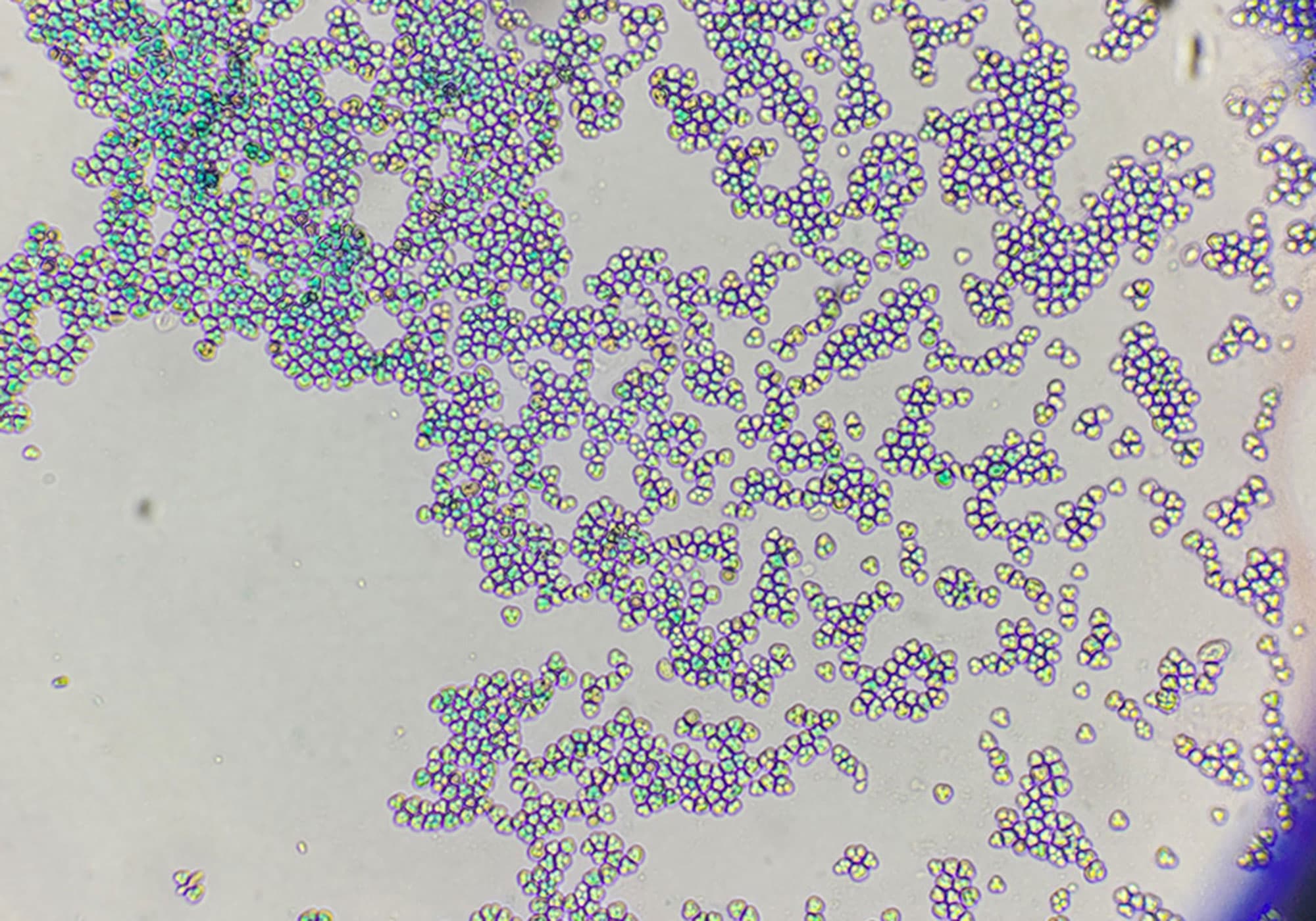

When it comes to microbes, the choices you make will shape the expression of your final spirit. Here are some key considerations.

From methods to ensure healthy fermentation to fementor choices to cleaning procedures, yeast selection, and time, the decision tree that a distiller follows when designing a fermentation regimen has tremendous impact on the character of the final product.

A distillery’s goals tend to influence its choice of equipment, as different spirits call for different ways to process grain or other fermentables. Here’s a primer.

Understanding the fundamentals of proper mashing or cooking can be essential to producing good spirits.

A distiller’s choice of still design can have a significant impact on their product lineup—and vice-versa.