Using Specialty Malts to Build Character in Spirits

Distillers can tap into the same kinds of flavorful malts that brewers commonly use to build additional flavor and complexity into their whiskeys.

75 articles in this category

Distillers can tap into the same kinds of flavorful malts that brewers commonly use to build additional flavor and complexity into their whiskeys.

Using the roller mill as an example, Village Garage head distiller Ryan Scheswohl makes the case for the kind of preventive maintenance that can preserve efficiency while saving costs and trouble in the long run.

In this clip from their video course, head distiller Ryan Scheswohl describes Village Garage’s on-grain, open-top fermentation method, from how many days they allow for the ferment to their streamlined transfer into the still.

When small distilleries have success, it can be tricky to navigate through expansion while keeping costs in check. Here are some key factors to consider when you’re making a plan and running the numbers.

In this clip from their video course: Village Garage head distiller Ryan Scheswohl explains how steel-jacketed pipes and clean steam make for a quicker, more efficient brewing process.

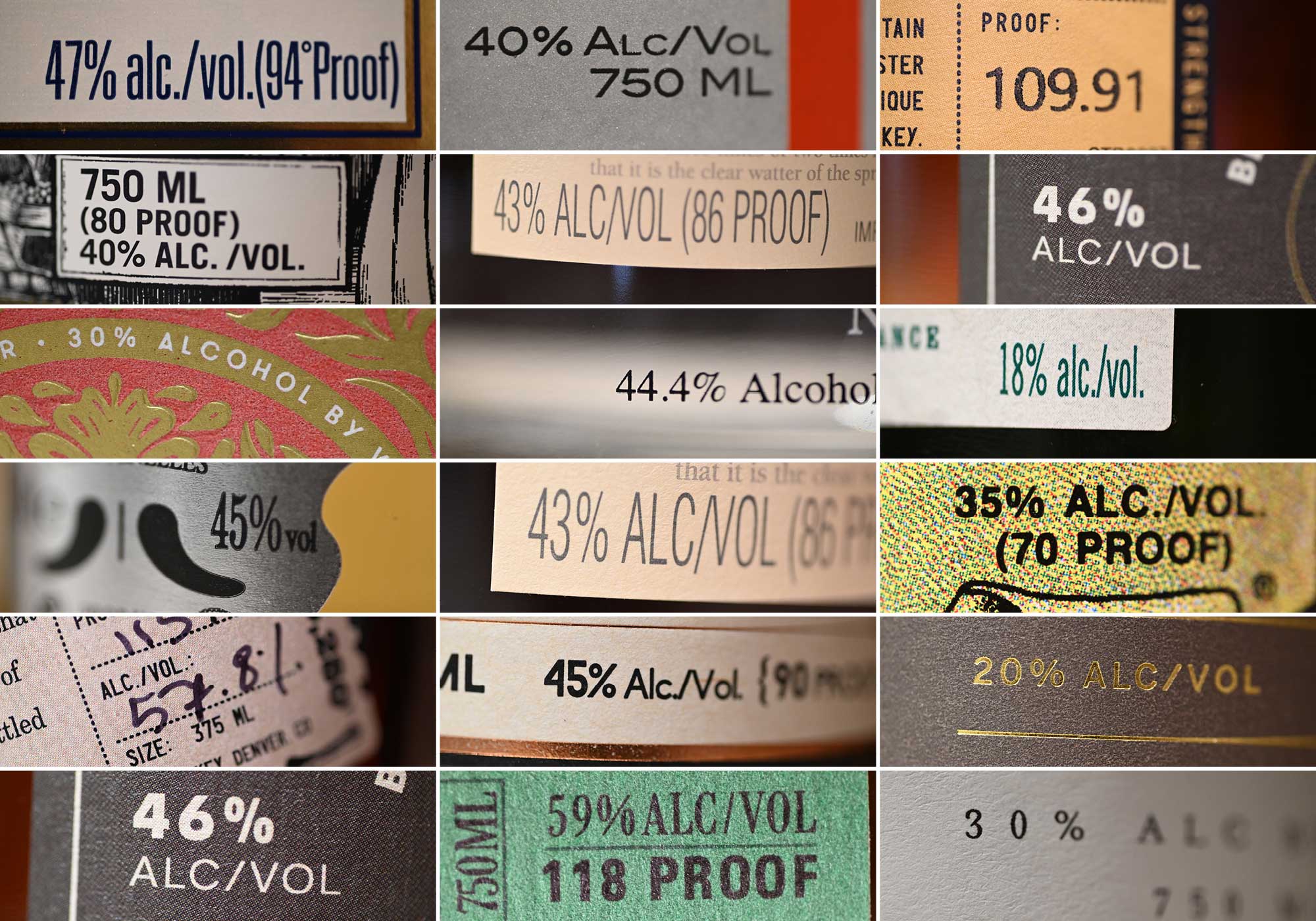

The strength at which distillers decide to bottle their products can have wide-ranging impact, from labeling laws to bartender preferences.

From fermentation to infusion, distillers are finding unique approaches to tap into the fruits of the cactus.

Choosing between steam, direct-fire, electric, and oil-heated equipment is a matter of budget, taste, and local code enforcement.

A critical part of properly caring for stainless steel in the distillery is properly cleaning it, ensuring a long lifespan for the equipment as well as the safety of your team.

Honey has more than mead up its beverage sleeve. Here’s how distillers work with it to balance bitterness, add floral notes, and speak to the nature around them.

While the smallest distilleries will never compete on volume, there are other areas where they can outmaneuver bigger players on experimentation, local ties, and small-batch appeal.

Smaller distilleries can tap into flavors and opportunities that may not be available at larger scale, whether that’s to support modest growth or simply to make the best possible spirit.

R&D distiller Mitch Mahar describes the innovation program that helps WhistlePig choose single-cask finishes worth pursuing, as well as potential threads for their annual Boss Hog special release.

In this clip from their video course, WhistlePig R&D distiller Mitch Mahar explains how the rye harvest can affect their choice of barrels for aging the spirit, as well as how cask placement can affect the final product.

A smaller space requires any producer to be flexible—but that nimbleness can also be a strength.

In a region better known for its characterful beers, an after-dinner schnaps is an important piece of the hospitality, as small distillers carry on family traditions and tap into the local bounty.

At their state’s first carbon-neutral distillery, two brothers are tapping into their family’s history, bringing a pea-based spirit out of Soviet times and into the 21st century.

There are multiple ways to accomplish the critical task of measuring alcohol content in the distillery. Here are four newer methods that are gaining popularity.

Industry members weigh in on the word “moonshine,” its evolving meaning in the American distilling world, and the propriety of using it on legally produced spirits.

Spirits that feature foraged ingredients offer unique flavors while appealing to locally minded drinkers.